There are numerous uses for a DC motor in today's technology and engineering fields. DC motors are utilized in everything from electric razors to automobiles. DC motors can be categorized as either brushless or brushed based on whether or not they employ brushes and commutators. We will be looking into the features of a brushed motor.

An internal commutated electric motor brushed for direct current power is known as a brushed motor. The first significant commercial use of electric energy to deliver mechanical energy was through brushed motors, and industrial and commercial buildings employed DC distribution networks.

If you have ever noticed sparks shooting from a power drill's motor cooling vents, you have already witnessed brushed motors in operation. Brushed motors are used in different electrical appliances, including RC cars which is why you need to know how they work.

What Is A Brushed Motor

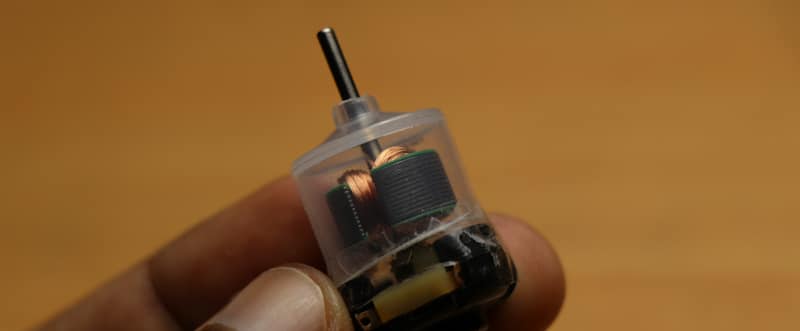

A brushed DC motor is the most basic and prevalent form of motor. This kind of motor may be found anywhere. Your phone undoubtedly has one within, enabling the vibration feature. Almost every moving toy uses brushed DC motors. Brushless DC motors are used to power cordless drills.

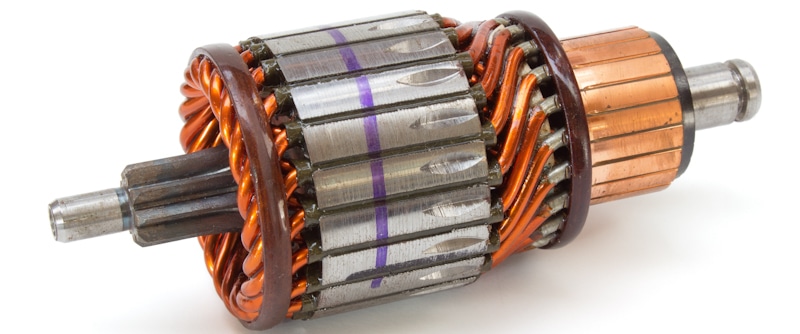

A revolving armature and permanent magnets are located inside the exterior body of a brushed motor. The term "stator" refers to the permanent magnets that remain stationary. The revolving armature, or "rotor," is equipped with an electromagnet. The rotor rotates 180 degrees in a brushed motor when the armature receives an electric current.

The electromagnet poles need to flip to move past the initial 180 degrees. As the rotor rotates, carbon brushes contact the stator, switching the magnetization and allowing the rotor to rotate 360 degrees. Brushed DC motors are industrially produced and often utilized, making them less expensive than other motor types.

All that is necessary to turn the motor is a DC voltage. The motor will operate more quickly with a greater voltage. The rotation axis is reversed when the polarity is changed. Brushed DC motors can be used without even requiring a microcontroller; you only need to attach one to a battery to get it going.

DC motors with brushes produce much torque at slower speeds. This is significant because the motor can start up quickly even with a load on it because of the strong starting torque. The motor's brushes eventually wear out because they physically scrape against the commutator when the motor is running.

As a result, brushed DC motors age more quickly than other types of motors. There is a great deal of electrical noise, which is not ideal for sensors or microcontrollers operating in a system. During operation, there is friction between the commutator and the brushes due to physical contact between the two components.

How Does A Brushed Motor Work

In brushed DC motors, the stator has magnets encircled by coiled coils in the rotor. The commutator is attached to a coil's two ends. When the commutator and brushes are in contact, the direct current electric power will flow via the brushes and coil. The commutator, in turn, links to electrodes called brushes.

However, when the coil turns, it comes to a point where the commutator and brushes do not touch again, cutting off the coil's current flow. Despite this, the coil keeps spinning due to its momentum restoring the current, which flows through a separate coil, by bringing the commutator and brushes back into contact.

The brushed DC motor keeps turning due to the repetitive switching of current flow. Brushed DC motors use direct current, and changing the voltage applied to change the speed is simple. Brushed motors employ mechanical switching to change the direction of the current flowing through the armature conductors and allow the armature to rotate.

A brushed motor has 6 different components. The most crucial parts found in practically all electrical motors are four of them. The rotor, brushes and commutator, and stator are the four parts that we will be discussing.

Stator

The stator creates a static magnetic field surrounding the rotor because it is the stationary component of the engine. Either electromagnetic windings or permanent magnets produce this magnetic field. The diverse designs of these motors are determined by the stator's structure and how the electric and magnetic windings are coupled to the power supply.

Brushes & Commutator

Brushed motors do not require a regulator to switch current in the primary winding, in contrast to other electric motor types. A brushed motor's windings are changed mechanically. A BDC motor's axle is where the commutator, a perforated copper sleeve, is mounted.

Carbon brushes move along the commutator and touch various commutator segments when the motor turns. A complex magnetic field is created inside the motor when a voltage is supplied across the brushes on these segments, coupled to various rotor windings.

Rotor

Several windings are used to create the rotor, often known as the "armature." These windings generate a magnetic field as they rotate. The rotor will turn because the magnetic poles field would face the opposing poles produced by the stator.

When the motor rotates, the windings are continuously energized in different sequences to prevent the magnetic poles produced by the rotor from interfering with those produced in the stator. Commutation is the term used to describe the current switching in the rotor windings.

How To Make A Brushed Motor Faster

A brushed motor usually goes much slower than a brushless motor. If you do not want to replace your brushed motor with a brushless one, there are a few methods you can apply to increase your brush motor performance. However, the efficiency will not last long.

To increase the speed of a brushed motor, you can get a motor with a lower turn or try to increase the voltage of your brushed motor. If the electronic speed control of the brushed motor can handle it, you should try tightening the hand winding with a flat wire; this is more effective than stock.

You can also replace the magnets and brushes in the brushed motor with a better one. Another way to make a brushed motor faster is to move the timing up from 20 to 24 degrees. This will greatly improve the speed of your brushed motor.

How To Tell If A Motor Is Brushed Or Brushless

Since brushless motors often have three wires and brushed motors typically only have two, it is usually possible to tell if you have a brushless or brushed motor by looking at the wires.

A brushless motor will not have any brushes inside, whereas a brushed motor will. Another main distinction between brushless and brushed motors is that brushless motors are powered electrically, whereas brushed motors are powered mechanically.

Brushed RC Motors

It might be very challenging to understand the differences in online specifications when buying an RC car. A lot of the lingo can be very perplexing if you do not have any general expertise with or knowledge of remote-controlled vehicles or automobiles. One of RC cars' most generally misunderstood concepts is the difference between brush and brushless.

Generally speaking, the primary benefit of brushed motors would be that they are much less expensive than brushless motors. They will typically cost less at retail than their brushless counterparts. In comparison to brushless motors, the system in brushed motors is simpler. They are a more economical choice because of how simple the wiring is.

Final Thoughts

In a concise statement, we may say that a brush is an electronic contact that transmits electricity from still wires to moving materials, most frequently in the form of a spinning shaft. Examples of typical applications include generators, alternators, and electric motors. How often the motor is operated and the power delivered affects the carbon brush's lifespan, affecting the entire brushed motor.

Shawn Manaher loves to play with new toys and dive into new hobbies. As a serial entrepreneur, work definitely comes first but there is always room for hobbies.

![What Is A Brushed Motor? [COMPLETE BEGINNER'S GUIDE]](https://hobbynation.net/wp-content/uploads/2022/08/brushed-motor-1-720x405.jpg)