Every RC car uses either a brushed or a brushless motor. The motor makes the RC car accelerate and move, either forward or backward. These two motors perform the job, although brushless motors function more efficiently than brushed motors. Brushless motors are the most popular RC motors.

A brushless RC motor can last for thousands of hours on average; this means if your RC car uses a brushless motor, you have the liberty to operate it for at least ten thousand hours (416 days); this is more than a year, unlike brushed motors that last for about one thousand to three thousand hours.

If you look at the motors in most RC cars, about seventy-five percent use a brushless motor. This is largely due to the fact that brushless motors are more efficient and durable than brushed motors.

Best Brushless RC Motors

One of the best modifications you can make to your RC car is to upgrade the motor. If your vehicle uses a brushless motor, you are lucky because there are many good brushless motors you can choose from to improve the performance of your RC car. However, you must ensure the motor is compatible with your remote-controlled car.

Traxxas Velineon 3500 4-Pole Motor

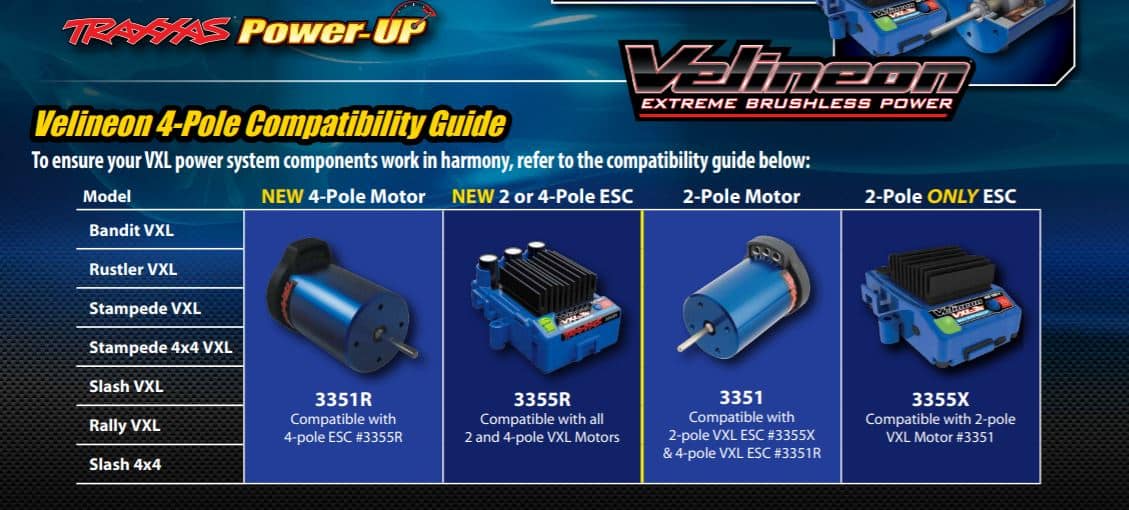

The Velineon 3500 4-Pole Motor is the best and the fastest RC motor available. This is one of the most expensive brushless motors, but it is worth the price. The Velineon 3500 4-Pole Motor is compatible with the Rustler VXL, Slash 4×4, Stampede VXL, Bandit VXL, Slash 2WD VXL, 1:10 Rally, and Stampede 4×4 VXL. This motor has an estimated lifespan of about 15000 hours.

This brushless motor comes with three different drive modes; training mode, racing mode, and sport mode. The training mode restricts the throttle by fifty percent, so there is little acceleration for a person learning to drive. The racing mode makes the car move as fast as possible, and the sport mode is for off-road activities.

The Velineon 3500 4-Pole Motor is compatible with 4-pole electronic speed control, 4-pole VXL electronic speed control, 4-pole VXL motor, 2-pole electronic speed control, 2-pole VXL electronic speed control, and 2-pole VXL motor. An RC car with this motor will maneuver smoothly and precisely.

This motor weighs 27 grams, uses 3.5 millimeters bullet connectors and 12-gauge Maxx cables. The motor's shaft length is 20.3 mm, the shaft diameter is 2.8 mm, and the total length is 77 mm. It has a kV rating of 3500 kV. The motor contains high-temperature magnets that supply loads of torque and speed to the vehicle.

Yosoo Mini Speed Reduction Motor

This is one of the most durable brushless motors available; it does not wear out easily, it is lightweight, supplies high torque, and has low RPM. Since this motor does not provide much speed, it is ideal for RC rock crawlers. It supplies enough power to male any RC car scale through unlevelled terrains.

The Yosoo Mini Speed Reduction Motor weighs 0.32 ounces, and it is 2.05 inches long, 1.22 inches wide, and 0.47 inches. This brushless motor is manufactured from metal, and it requires 12 volts. This brushless motor is not only suitable for RC cars but also robot models and DIY engine toys. Yosoo brushless engines last for about 8000 hours.

Do Brushless Motors Wear Out?

No, brushless motors do not wear out. The main difference between a brushed motor and a brushless motor is that the former has brushes and commutators that wear out with time while the latter does not. In a brushed motor, electricity is generated by the brushes and commutators pushing against each other.

However, brushless motors do not need commutators and brushes to produce power. More efficient technology is used, making brushless motors better than brushed motors. Brushless motors were manufactured as an improvement to brushed motors in the 1960s.

Brushless motors have higher efficiency and performance. They also possess a lower susceptibility to mechanical wear. Brushless motors can function for tens of thousands of hours since there are no brushes to wear out. Both motors operate on the principle of repulsion and magnetic attraction; however, a brushless motor uses electronic commutation to rotate the magnetic field.

Brushless motors produce less heating, are better adapted, provide better performance and generate no friction. With a brushless motor, you do not have to worry about replacing worn-out brushes. It is also controlled with a device known as the controller. The rotation is created by the transformation of DC to a three-phase variable frequency current which supplies the motor coils.

All brushless motors come with a fixed stator that holds the coils and a mobile rotor where the permanent magnets are glued. Most brushless motors possess an internal rotor that can turn as fast as 100000 rpm.

What Causes A Brushless Motor To Fail?

Due to highly rated brushless motors, many people are of the impression that they cannot fail. This is a huge misconception of brushless motors. There are some things that can cause a brushless motor to shut down. The major cause of the failure of a brushless motor is the current.

The current of a brushless motor is related to the load of the motor. As the load increases, so does the current. The current is what contributes to heat; hence as the current increases, the heat increases. The amount of waste heat of a brushless motor equals the amount of current generated by the motor. Hence, all the waste heat contributes to the failure of the brushless motor.

When there is much heat in the motor's windings, it becomes so hot that the rotor magnet gets demagnetized. As brushless motors operate on the principle of magnetic attraction, if the rotor magnet is demagnetized, the general function of the motor is affected. Demagnetization causes the motor's kV to increase; hence, the motor will try to hit higher RPMs.

When the brushless motor tries to hit higher RPMs, a higher current draw will occur. This will lead to a high building of heat in the windings, which will allow the enamel coating on the windings to burn away. Once this happens, the brushless motor is as good as gone.

Do Brushless Motors Need Maintenance?

Yes, brushless motors need maintenance. Every electronic requires maintenance for optimum performance; hence a brushless motor is no exception. However, unlike a brushed motor, a brushless motor requires little maintenance. The brushless motors have to be inspected and cleaned.

Some of the maintenance a brushless motor requires are:

- The chassis should be cleaned with an air compressor to get rid of all accumulated dirt and dust. You can also use a toothbrush to remove dirt.

- Make sure the speed control is never loose; if you can wiggle it easily, it is loose.

- Check the speed control for damaged insulation and frayed wires. If there are any damaged wires, repair them with liquid electrical tape or heat-shrink tubing.

- Make sure you always clean the motor by wiping off all dirt and dust.

- Always re-lubricate the bearings of the brushless motor with a drop of bushing oil in each bearing.

When cleaning the brushless motor, it is important that you make sure to disassemble the motor. Maintaining your brushless motor from time to time prolongs its lifespan and enhances performance.

Final Thoughts

Brushless motors are the most preferable and suitable motor for RC cars; their lack of brushes and commutators makes them last longer, stronger, more durable, and efficient. However, brushless motors are more expensive than brushed motors. Brushless motors have a longer lifespan than brushed motors because they do not have parts easily affected by wear and tear.

Shawn Manaher loves to play with new toys and dive into new hobbies. As a serial entrepreneur, work definitely comes first but there is always room for hobbies.